Brushless DC (BLDC) motors1 are often hailed as the superior choice in many applications due to their efficiency and longevity. However, like any technology, they come with a set of inherent drawbacks that engineers and designers must consider. Are you contemplating a BLDC motor for your next project, but keen to understand the full picture before committing?

While offering high efficiency and long life, brushless motors primarily disadvantage users with their higher initial cost2, increased control system complexity3, and the potential for electromagnetic interference (EMI)4 due to their electronic commutation.

In my years of designing industrial automation systems and working with various motor types, I have seen firsthand the allure of BLDC motors. They promise so much in terms of performance. Yet, my experience has also taught me to look beyond the hype and understand the practical challenges they present. For example, integrating the necessary control electronics can sometimes be more complex than the mechanical design itself, a fact that often surprises those new to BLDC systems.

Why Are Brushless Motors More Expensive?

When you first look at BLDC motors, their price tag often stands out compared to brushed motors of similar power. This higher cost is not arbitrary; it stems from fundamental differences in design and manufacturing. In my work, budgeting for components is always a tightrope walk, and understanding where the costs come from is crucial for making informed decisions.

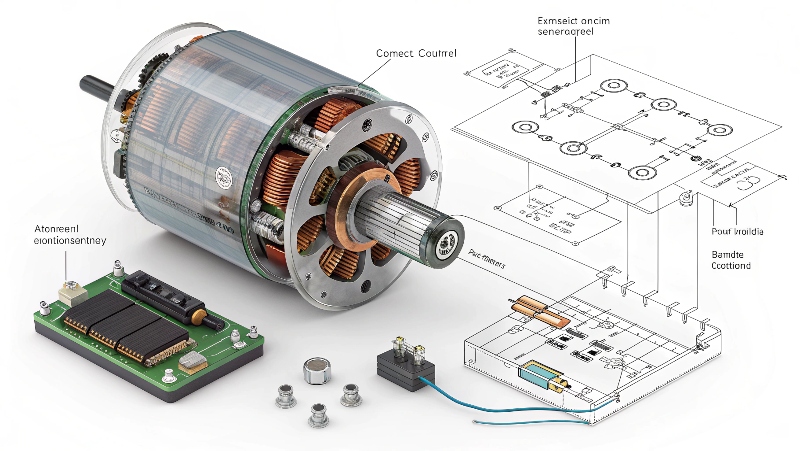

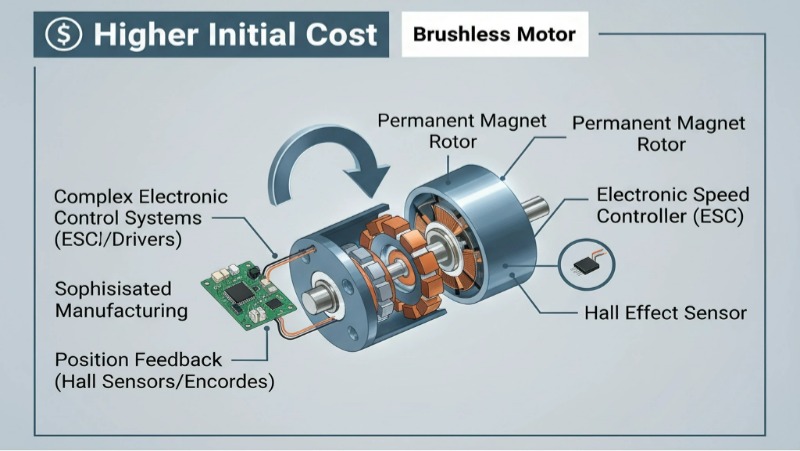

Brushless motors incur higher initial cost2s due to the necessity of complex electronic control systems (ESCs or drivers) for commutation, more sophisticated manufacturing processes for their permanent magnet rotors5, and often the integration of Hall effect sensors6 or encoders for position feedback.

Secondly, the manufacturing process for BLDC motors can be more complex. BLDC motors typically use permanent magnets in their rotors, which need to be precisely assembled and sometimes glued into place. These high-performance magnets (like Neodymium magnets) are more expensive than the copper windings used in a brushed motor's rotor. The stator windings in BLDC motors are also often wound in specific configurations (e.g., Wye or Delta) and require careful insulation, which sometimes involves more specialized winding machines. The precision required for magnet placement and stator winding contributes to higher manufacturing costs.

Here is a comparison of cost drivers between brushed and brushless motors:

| Feature/Component | Brushed DC Motor Cost Drivers | Brushless DC Motor Cost Drivers |

|---|---|---|

| Commutation System | Carbon brushes, mechanical commutator | Electronic Speed Controller (ESC/Driver), control logic |

| Rotor Construction | Copper windings, laminated iron core | Permanent magnets (e.g., Neodymium), rotor shaft |

| Stator Construction | Permanent magnets or field windings | Copper windings, laminated iron core |

| Position Feedback | Not typically required for basic operation | Hall effect sensors6, encoders (optional but common) |

| Manufacturing Complexity | Relatively simpler winding and assembly processes | Precision magnet assembly, sophisticated winding, controller integration |

| Overall System Cost | Lower | Higher |

This table clearly illustrates that while BLDC motors offer performance advantages, these come at a premium driven by advanced electronic control and more complex componentry. For a product designer, this means a careful cost-benefit analysis must be performed to justify the investment in BLDC technology.

What Are the Control and EMI Challenges with Brushless Motors?

Beyond the financial aspect, the technical intricacies of controlling BLDC motors can be a significant hurdle. My work in industrial automation often involves integrating various motor types into complex systems, and BLDC certainly presents unique challenges, particularly concerning control complexity and electromagnetic interference (EMI)4. These are not minor issues; they can impact system reliability and compliance.

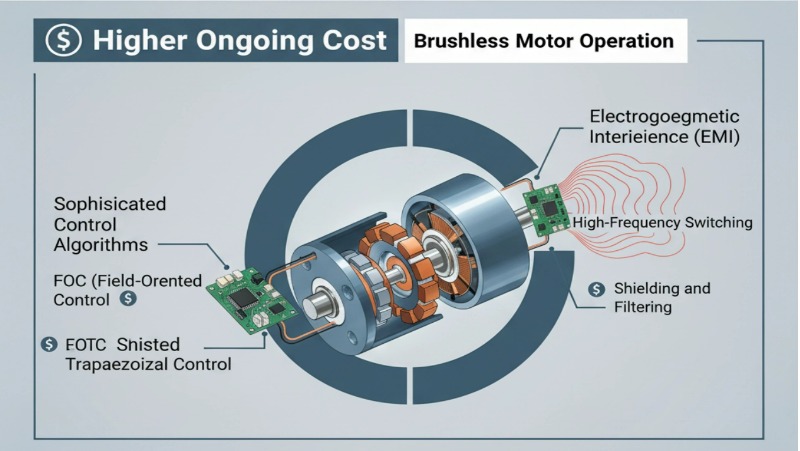

The sophistication of BLDC control is one of its primary disadvantages. Since there are no brushes to mechanically switch the current, an external controller must electronically perform this task. This requires knowledge of the rotor's exact position at all times. This position information can be obtained using Hall effect sensors embedded in the motor, requiring additional wiring and potential points of failure. Alternatively, "sensorless" control methods can estimate the rotor position by analyzing the back-EMF9 generated in the unenergized winding. While sensorless control reduces hardware complexity, it demands more powerful microcontrollers and more complex algorithms, such as Field-Oriented Control (FOC)10 or trapezoidal control. These algorithms require significant processing power and careful tuning to achieve optimal performance, especially across varying loads and speeds. This complexity translates directly into longer development times and potentially higher development costs for the engineering team.

Then there is the issue of Electromagnetic Interference (EMI). The electronic commutation in BLDC motors involves high-frequency switching of currents in the stator windings. This rapid switching creates electromagnetic noise that can interfere with other sensitive electronic components in the system, such as sensors, communication modules, or even the power supply. In critical applications, this EMI can lead to unreliable operation or failures. Mitigating EMI requires careful PCB layout11, shielding, filtering components (e.g., capacitors, chokes), and proper grounding techniques, all of which add to the system's complexity and cost. When designing compliant products, EMI testing is a mandatory and often challenging part of the certification process, and BLDC motors can make this task significantly harder.

Let us summarize these technical disadvantages:

| Disadvantage Category | Specific Challenge | Engineering Implications |

|---|---|---|

| Control Complexity | Requires precise rotor position sensing (sensors or sensorless) | More complex control algorithms (FOC, trapezoidal), powerful microcontrollers. |

| Need for specialized motor drivers/ESCs | Higher cost of control electronics, longer development cycles. | |

| EMI Generation | High-frequency switching currents in stator windings | Potential interference with other electronics, signal noise. |

| Compliance with EMC regulations | Requires shielding, filtering components, careful grounding, extensive testing. | |

| Reliability of Electronics | Control electronics are susceptible to heat, voltage spikes | Requires robust circuit design, proper thermal management12 for controller. |

| Minimum Operating Speed | Sensorless control can struggle at very low speeds | May not be suitable for applications requiring precise control near stall. |

These disadvantages highlight that while BLDC motors are powerful and efficient, they are not a "plug-and-play" solution. They require a deeper understanding of electronics, control theory, and electromagnetic compatibility. For specific applications where cost, footprint of electronics, or EMI sensitivity are major factors, these drawbacks can influence the design choice towards other motor types, even if it means sacrificing some efficiency or lifespan.

Conclusion

While highly efficient and long-lasting, brushless motors come with significant drawbacks including a higher initial cost2 due to intricate electronic control systems and manufacturing. They also pose challenges with control complexity, requiring sophisticated algorithms, and can generate considerable EMI, demanding careful design for isolation.

Understanding both sides of BLDC motors can help you make informed decisions for your projects. ↩

Explore the reasons behind the cost to better budget for your motor projects. ↩

Learn about the intricacies of control systems to enhance your engineering knowledge. ↩

Discover how EMI can impact your designs and how to mitigate its effects. ↩

Explore the advantages of permanent magnets to enhance your design choices. ↩

Understanding Hall effect sensors can improve your control system designs. ↩

Gain insights into ESCs to understand their role in motor performance. ↩

Gain insights into the importance of circuitry in achieving optimal motor performance. ↩

Learn about back-EMF to deepen your understanding of motor operation. ↩

Explore FOC to enhance your knowledge of advanced motor control techniques. ↩

Learn about PCB design to ensure reliable motor operation and minimize EMI. ↩

Explore thermal management to ensure the reliability of your motor systems. ↩

" alt="Article Image" class="w-full h-full object-cover">

" alt="Article Image" class="w-full h-full object-cover">